The Supply Chain is often thought of as a collection of parts and sub-assemblies that are needed to build a specific product.

A key element in your supply chain are your suppliers (or vendors) and their reliability in meeting your delivery and cost expectations.

On this page, we explore the multiple factors that go into selection the right parts and their suppliers.

The Supply Chain is the metaphorical set of links where suppliers move material from one company to the next, adding value in each step, until it finally arrives at your company.

Unless you are the end user, you’re another link in that chain; so is Product Resources.

Suppliers can add value by processing raw material, transforming it into something more useful (to you), moving that material, storing that material, stocking large quantities of it, aggregating that material into more complex products, testing and calibrating assemblies of materials, installing and setting up products, or supplying the IP necessary for that product to do the job the end customer needs.

Suppliers, sometimes called Vendors, are a critical part of a manufacturing operation. We prefer the term “Supplier” rather than “Vendor” because a vendor will sell you what they have, where a supplier will sell you what you need. It’s a subtle point, but with the (somewhat hopeful) attitude that you are in control of what you are buying, you want to deal with suppliers.

A supplier will work with a purchase specification detailing exactly what you need or provide you with a datasheet so you can count on the product meeting a standard that is agreed upon. When you purchase a custom component, to a drawing or document that you generated and supplied, you work with suppliers. With a vendor, what you are buying is less clear, or the provenance of the product is less clear.

Some examples:

- Digikey, Arrow, and other distributors – Suppliers. You may be buying what they have to offer, but there is a datasheet which you can lean on to ensure you get what you ordered every time. Top tier distributors also purchase directly from manufacturers (e.g., TI, Analog Devices) so you know that the chain of quality is intact – these parts are not sourced on the secondary market.

- Machine shops, PCB Assembly shops, Contract Manufacturers – Suppliers. They build what you order, to your specifications.

- Manufacturers – Suppliers. They sell product that they design and build, but they publish specifications that they stand behind. You can use that specification in your design and (with some verification and a quality system) rely on the consistency.

- McMaster-Carr, mostly supplier. They don’t manufacture and they can change sources, but they do have specifications and drawings for most parts, so you can have reasonable confidence that you will get the same part. If it is a critical part, there may be too much risk for McMaster, but you should evaluate that on a case-by-case basis. For generic parts like threaded hardware, they are a good source with fast delivery. For large hardware orders, there are other sources with better pricing.

- Open Market Distributors (Brokers) – mostly vendors. The datasheets are there, but the quality chain may have been broken since they purchase “surplus” parts. Also, beware of counterfeit product, especially Integrated Circuits. When a single TO-99-8 Op Amp is selling for $600 based on some very tight specifications, it is difficult to know what you are installing – there is too much incentive to substitute lesser parts and change the part number. These open-market distributors don’t change the part numbers, but they buy from many secondary sources; be sure they have the experience and a quality plan to eliminate counterfeit parts. Some of them have in-house certified test labs for that purpose. There is a danger that using parts from these sources will force you to “inspect the quality into the part”, rather than rely on the supplier for certification.

- Amazon, Alibaba, eBay, hobbyist websites – Vendors. They sell you what they have from their multiple suppliers. You can get lucky and find exactly what you need, but it is difficult to know if that product will be there the next time you order. Even if the component is name-brand, it is hard to judge the quality since it is not clear who has handled the product since it was built. It is also hard to order the same part and get consistency. They may sell one brand, then substitute another that they claim is the same, but may have differences that you cannot tolerate. Remember, you are in manufacturing now, there is no time for engineering to verify each part as it is received; it must be known to be exactly what is expected.

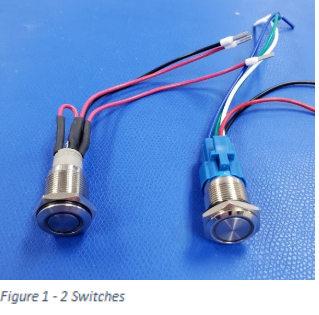

In Figure 1 (below), there are two switches, ordered from the same company with the same part number. On the left is the original and, on the right, the newest switch received on the latest order. The original switch did not have wires attached, we added those, but the newest switch was received with flying leads. Better, right? Maybe, but that’s not the point. It’s different, so the design was impacted.

The switch will fit into the same mounting hole, so that’s good. Downloading the datasheet, the specifications are for the original switch, not the new one, so we can’t confirm electrical characteristics. No information on the wiring of the switch, so we had to figure that out. Long story short, production stopped until we figured out how the new switch was wired and updated the documentation to show how to implement the new part in the design. We were obligated to change the manufacturing documentation to note the changes and how the new switch would be processed. We could have rejected the parts and sent them back due to the change, but this part was consigned to us by our customer.

Finally, what kind of controls are in place in a company that swaps obviously different switches in their inventory? What if the switches looked the same but had different characteristics, for instance a lower rated current or voltage? The new switch may be unsuitable for the application, and it isn’t good enough that the supplier thinks it’s OK.

It is also called a supply chain because it can be disrupted by the weakest link. Any supplier along the way can have an issue and cause a delay. To make the supply of your product more resilient, it is important that you choose the components carefully, especially items that are sole-sourced. These issues can be minimized by having multiple qualified suppliers for the parts. In the case of parts in distribution, multiple distributors are likely to have the part in stock so if one runs out, you can jump to another; that’s the easy one. It is also important to have multiple sources for the machined parts or sheet metal parts. If you use only a single machine shop, it will take longer to switch to another if there is a problem and the part is complex enough to require more than standard process controls.

Choose your suppliers carefully. When you are building hundreds or thousands of products each year, a weak supply chain will cause endless emergencies. Suppliers with good quality systems and control of their supply chain will make the process easier.

Our Supply Process

Product Resources uses a computerized ERP system for material planning. This system generates material requirements for our purchasing group to fulfil. Suppliers are chosen based on their ability to supply the part(s) that meet our quality requirements, delivery requirements, and pricing needs.

Suppliers are categorized based on our experience with their on-time and quality performance. New suppliers are assigned a probationary rating and additional incoming quality scrutiny is tightened until the supplier has met goals for quality. Once those goals are met, the supplier is moved to the Approved category and our normal processes apply. Note that probationary status is also part-based, meaning that a new part being purchased from an existing, Approved supplier is flagged for additional scrutiny until quality goals are met – we are convinced that the supplier has the product’s manufacturing process under control.

We work closely with suppliers to be sure that there are no misunderstandings about the components we require and if any issues arise, we work with them until it is resolved. It is rare that we are forced to change suppliers to resolve a problem. Our Supplier Review Board meets periodically and reviews supplier performance and sends reports to our suppliers on how they are meeting our quality and on-time delivery requirements.

With new customers occasionally come new suppliers. We are happy to have the opportunity to work with new suppliers, but the same rules must apply to our customer’s suppliers as to our own.